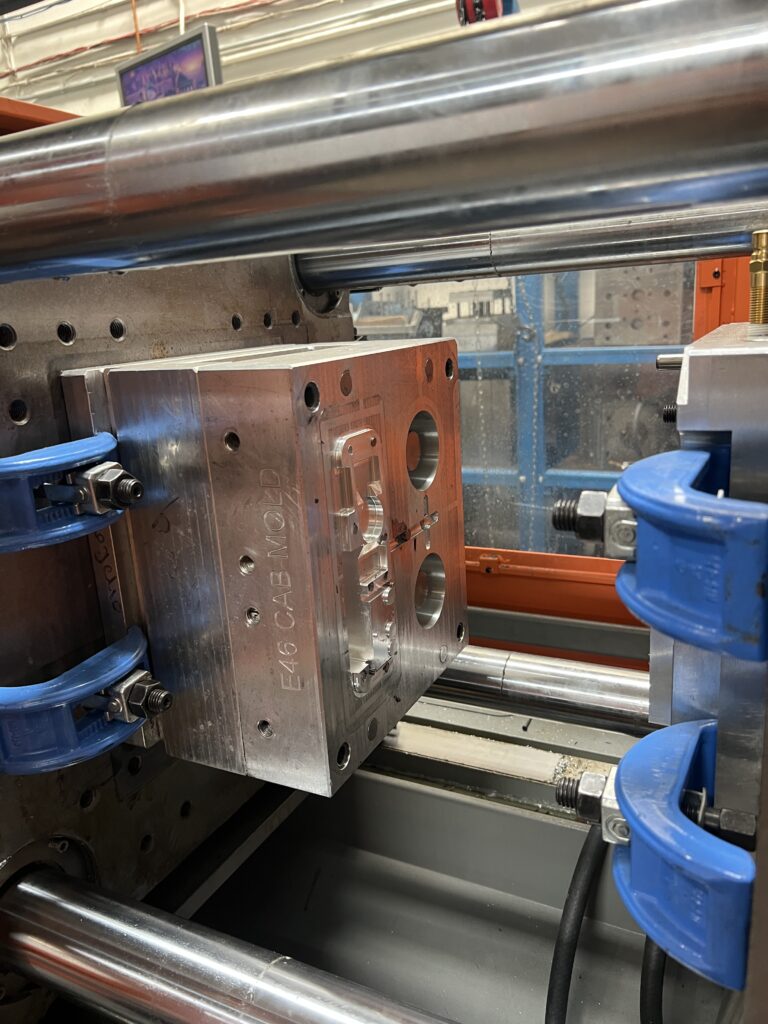

Plastic Injection Molds & Molding Services

High-Quality Precision Molding Solutions from JenBro Manufacturing

At JenBro Manufacturing, we specialize in the design, development, and production of custom plastic injection molds and injection-molded parts tailored to meet the unique demands of a wide range of industries. With decades of experience and state-of-the-art equipment, we deliver reliable, scalable, and cost-effective solutions that ensure consistency, quality, and performance.

Industries We Serve

Our plastic injection molding capabilities support a variety of industries, including:

- Automotive – Durable parts for under-the-hood components, interior trim, lighting housings, and more

- Consumer Products – Everyday goods including appliance parts, kitchen tools, and plastic enclosures

- Medical & Healthcare – Precision-molded components for diagnostic devices, housings, and single-use medical products

- Electronics – Lightweight, heat-resistant parts for enclosures, connectors, and insulators

- Industrial & Construction – Structural components, tool handles, and housing parts built for strength and endurance

- Aerospace & Defense – Tight-tolerance parts for mission-critical applications

- Agricultural Equipment – Weather-resistant parts for tools and equipment used in rugged environments

Why Choose Plastic Injection Molding?

Plastic injection molding offers a range of advantages for manufacturers seeking high-volume production, precision, and design flexibility:

- High Efficiency & Output Rates – Fast cycle times and automation make this ideal for large production runs

- Consistent Quality & Repeatability – Each part is produced with identical specifications for tight tolerances

- Cost-Effective – Especially for high volumes, injection molding reduces per-part cost significantly

- Material Versatility – We work with a broad range of thermoplastics, including high-performance and engineering-grade resins

- Complex Designs – Injection molding allows for intricate geometries and complex part designs in a single shot

- Minimal Waste – Optimized processes reduce scrap and promote sustainability

Our Capabilities

At JenBro Manufacturing, we combine engineering expertise with cutting-edge technology to deliver superior results:

- Custom Mold Design & Tooling – In-house design team uses CAD/CAM software and mold flow analysis to create efficient, durable tools

- Short-Run to High-Volume Production – Flexible options for startups, pilot runs, and ongoing mass production

- Insert Molding & Overmolding – Integrate metal or other materials into plastic parts for added strength or functionality

- Tight Tolerances – High-precision molding ideal for regulated industries like medical, aerospace, and electronics

- Material Selection & Sourcing – We help you choose the best materials based on strength, temperature resistance, and regulatory needs

- Secondary Operations – Including ultrasonic welding, pad printing, assembly, and packaging

Partner with JenBro Manufacturing

From prototype to production, JenBro Manufacturing is your trusted partner in plastic injection molding. We’re committed to quality, reliability, and on-time delivery—backed by a responsive team that puts your success first.