Precision Machining for Pump Components

Reliable, High-Tolerance Machined Parts for Demanding Applications

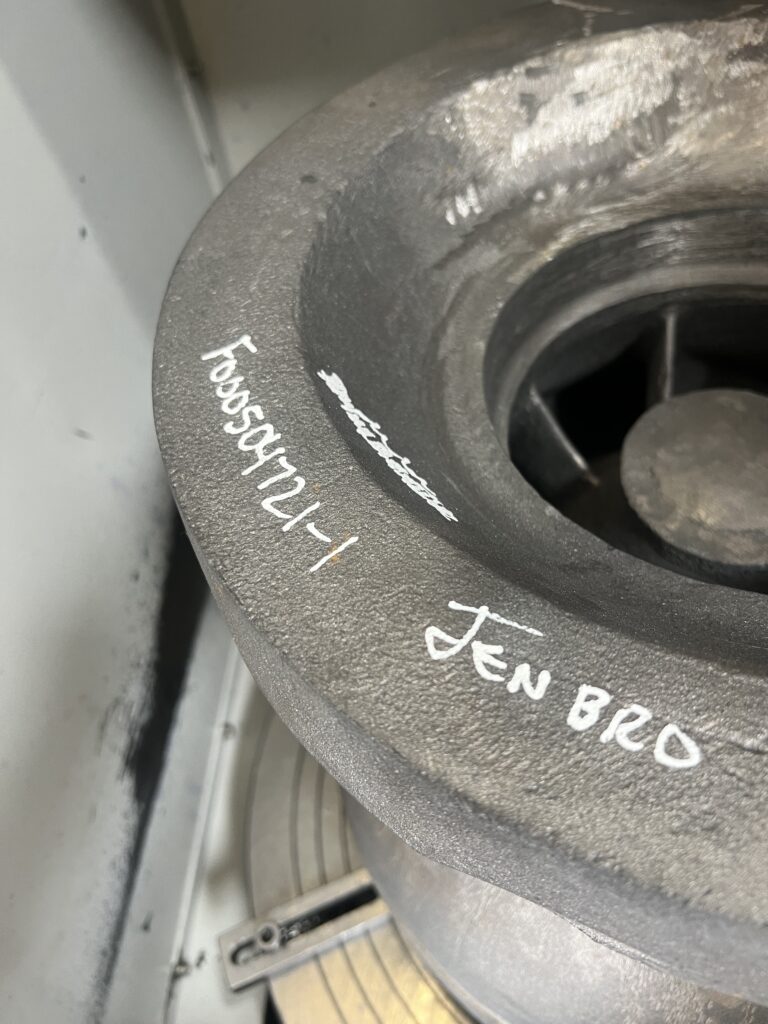

At JenBro Manufacturing, we specialize in the precision machining of pump components used in critical fluid and gas handling systems across a wide range of industries. From prototyping to production, we deliver high-performance parts with tight tolerances, durable materials, and consistent quality—ensuring your pumps operate efficiently, reliably, and safely.

Industries We Serve

Our expertise in machining pump components supports a variety of demanding industries:

- Oil & Gas – Machined pump housings, impellers, shafts, and seals for upstream, midstream, and downstream applications

- Water Treatment & Utilities – Components for wastewater pumps, filtration systems, and pressure boosting equipment

- Chemical Processing – Corrosion-resistant parts for aggressive media and high-temperature operations

- Food & Beverage – Hygienic pump parts that meet sanitary standards for clean-in-place (CIP) systems

- Pharmaceutical & Biotech – Precision components for metering, dosing, and transfer pumps used in regulated environments

- Agricultural & Irrigation – Rugged components built to withstand abrasive conditions and variable flow demands

- HVAC & Industrial Systems – Durable parts for circulation, chiller, and process pumps

Benefits of Precision-Machined Pump Components

JenBro Manufacturing delivers pump parts that meet your most exacting specifications, offering benefits such as:

- Tight Tolerances – We machine to exact dimensional specifications, ensuring perfect fit and optimal performance

- Improved Efficiency & Longevity – High-quality surfaces and materials reduce wear and energy losses over time

- Material Versatility – Stainless steel, bronze, aluminum, plastics, and exotic alloys for corrosion, pressure, and temperature resistance

- Cost-Effective Production – Scalable services that lower costs over large production runs while maintaining consistent quality

- Custom Designs – Ability to machine intricate geometries and proprietary component designs

Our Capabilities

JenBro’s machining division is equipped with advanced technology and skilled machinists, delivering the precision and performance today’s pump systems demand:

- CNC Wire EDM, Milling & Turning – Multi-axis machines capable of complex geometries and high repeatability

- Component Types – Pump bodies, impellers, covers, wear rings, bearing housings, couplings, shafts, sleeves, and casings

- Prototype to Production – Support for one-off custom components, limited batches, or full-scale production runs

- CAD/CAM Integration – Streamlined from design to production for accuracy and efficiency

- Secondary Services – Heat treating, surface finishing, coatings, and precision inspection for complete turnkey solutions

- Material Expertise – Al Bronze, Stainless steel, titanium, Inconel, Hastelloy, Super Duplex steel and more

Why Choose JenBro Manufacturing?

With a reputation built on precision, quality, and reliability, JenBro Manufacturing is a trusted partner to OEMs, engineering teams, and pump manufacturers nationwide. We understand the critical role each pump component plays and apply strict quality control processes to ensure every part we deliver meets your performance standards.